Hydraulic calculation of the pipeline for the transportation of petrothermal energy according to the pipe-in-pipe scheme

Журнал: Научный журнал «Студенческий форум» выпуск №33(126)

Рубрика: Технические науки

Научный журнал «Студенческий форум» выпуск №33(126)

Hydraulic calculation of the pipeline for the transportation of petrothermal energy according to the pipe-in-pipe scheme

Abstract. The article discusses ways to solve problems associated with the use of various types of resources. New methods of extracting petrothermal energy from the bowels of the earth are proposed, and an analysis of methods for obtaining petrothermal energy is carried out.

Keywords: petrothermal energy, heat power engineering, renewable resources.

Introduction. Energy is an integral part of human life. Excessive use of resources that, after full use, cannot be restored, is a problem today. Due to the fact that reserves are being depleted, people need to look for new ways to extract resources that have not yet been affected, which can have a positive impact on the planet as a whole.

In today's world, people are looking for more economical ways of consuming non-renewable and renewable energy sources and various fuels. Many countries are developing at a fast pace, so they need to make every effort to find an alternative source of energy [4,5].

Main part. In this work, it was proposed to extract heat from rocks that are deep underground. This section of geothermal energy is petrothermal.

Deep-seated rocks have a huge amount of energy due to ongoing processes in the depths of the earth. The thermal potential of the earth is supported by:

-tectonic displacement of plates and changes in the earth's crust;

-decay of radioactive elements

-continuous physical and chemical processes.

The idea of using petrothermal energy was proposed back in the 20th century. Petrothermal power plants already exist in France, the USA, Germany and other developing countries.

It should be noted that another area of geothermal energy is hydrothermal. Geothermal energy is more popular because it is easier to implement. However, its implementation is possible only where there are favorable geothermal waters.

As for petrothermal energy, its resources are practically inexhaustible, readily available everywhere and convenient to use, in contrast to solar and wind energy [2,3].

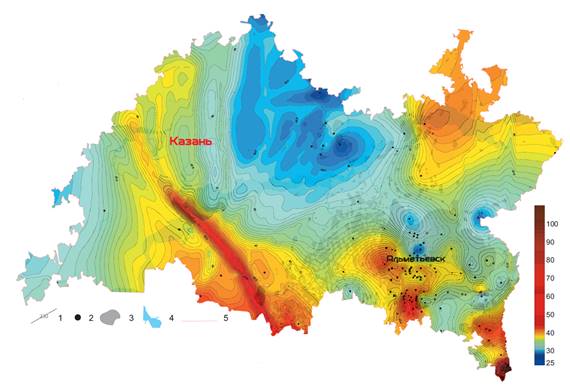

Scientists use calculation and experimental methods to extract information on the temperatures of rocks, the data obtained make it possible to build maps with temperature fields and isotherms. Analysis of the constructed maps can help to find more favorable spaces for the introduction of an alternative type of energy. On the basis of experimental high-precision temperature measurements in solid and superdeep wells, which were carried out in the territory of Tatarstan, isotherm maps were constructed, which are shown in Fig. 1 and Fig. 2 along the top of the crystalline basement and at all possible depths up to 12 km. A pronounced inhomogeneity of the thermal field is characteristic of all depths. Zones with increased temperature values, indicating high heat fluxes from the bowels, and, in accordance with this, the highest degree of fragmentation and fracturing of rocks and the presence of intense processes of convective heat and mass transfer, have all the chances to be recommended for deep drilling [1].

Figura 1. Isotherm map for the top of the crystalline basement

Figura 2. Isotherm map at an absolute elevation of -12000m

Methods for pumping petrothermal energy from the bowels of the earth.

Extraction of energy from the bowels of the earth is a very difficult process, however, it is possible to apply all kinds of methods for pumping petrothermal energy.

Heat exchangers are considered to be a significant object for the development of the project during the study, due to the fact that they will be used to pump both cold and hot heat carriers.

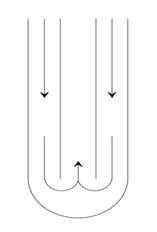

One of these methods is "pipe in pipe" Pic. 3. This method does not have problems with the transportation of deep earth rock heat to the surface. In practice, the method of extracting deep-seated heat is used everywhere, based on the direct contact of the heat carrier with the subsoil. In the mass of high-temperature rocks, artificial hydraulic fracturing creates a fracture concept that guarantees independent circulation and heating of the thermal carrier. The pipe is installed to a depth of 5-10 km. Further, hot water flows from the bowels of the earth through a pipe. Hot and cold heat carriers move in two different channels [6].

Figura 3. Scheme "pipe in pipe"

Let us calculate the hydraulic friction head losses when the fluid moves in the pipe to select the pump [6].

![]()

![]()

![]() (recommendation in the literature)

(recommendation in the literature)

![]() (oil heating in winter for pumping)

(oil heating in winter for pumping)

![]()

![]()

where Q- the amount of heat in W required to compensate for heat loss.

![]() - final temperature to which it is necessary to heat water

- final temperature to which it is necessary to heat water

![]() - initial temperature

- initial temperature

с- specific heat capacity of water equal 4200![]()

![]() , because

, because ![]()

![]()

![]()

![]()

![]()

![]() (selection of the standard according to GOST)

(selection of the standard according to GOST)

![]()

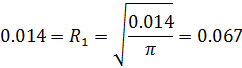

Let us find the frictional head loss when water moves in a pipe with an inner diameter

Pipe length ![]()

![]() (100см/с)

(100см/с)

From the table, we find the kinematic viscosity of water at a given temperature

![]()

![]()

We conclude that the flow regime in the pipes is turbulent.

We find from table X11.1 the value of the absolute equivalent roughness (A.D. Altshul, P.G. Kiselev - Hydraulics and Aerodynamics)

![]()

We calculate the value of the coefficient of hydraulic friction

The head loss will be equal to

Water at temperature ![]() flows in a pipe consisting of two concentric galvanized steel pipes

flows in a pipe consisting of two concentric galvanized steel pipes ![]()

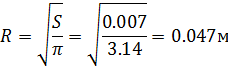

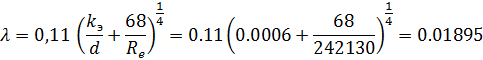

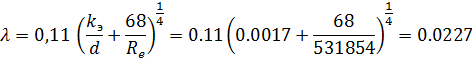

Determine sequentially the area of the free cross-section

![]()

Wetted perimeter ![]()

Equivalent pipe diameter ![]()

Relative roughness ![]()

![]() (100см/с)

(100см/с)

Reynolds number

![]()

Hydraulic friction coefficient

Head loss

Choosing a pump by Grundfos

Sentence text

SP 30-46

Submersible borehole pump designed for pumping clean water. Can be installed both vertically and horizontally. All metal parts are made of stainless steel, EN 1.4301 (AISI 304), which provides high corrosion resistance. This pump is approved for pumping potable water. The electric motor is equipped with a Grundfos Tempcon sensor, which, through power line communication together with the MP204 control panel, allows temperature control. The electric motor is designed for direct on line starting at full voltage (DOL).

|

Liquid: |

||||

|

Working fluid: |

|

Water |

||

|

Maximum liquid temperature: |

|

50 °C |

||

|

|

|

|

||

|

Technical data: |

|

|

||

|

Pump speed at which its characteristics are calculated: |

|

2900 Rpm |

||

|

Current calculated flow: |

|

31.33 м³/h |

||

|

Total hydrostatic head of the pump: |

|

342 м |

||

|

Mechanical seal for motor: |

|

SIC/SIC |

||

|

Performance tolerances: |

|

ISO9906:2012 |

||

|

Installation: |

|

|

||

|

Pump outlet: |

|

R3 |

||

|

Electric motor diameter: |

|

6 inch |

||

|

|

|

|

||

|

Electrical data: |

|

|

||

|

Electric motor type: |

|

FRANKLIN |

||

|

Rated power - P2: |

|

45 kW |

||

|

Energy (P2) required for the pump: |

|

45 kW |

||

|

Supply frequency: |

|

50 Hz |

||

|

Rated voltage: |

|

3 x 380-400-415 В |

||

|

Rated current: |

|

95-89.5-89 A |

||

|

Electric motor number: |

|

82193122 |

||

|

Windings: |

|

Enamelled |

||

|

|

|

|

||

Selection result

|

A type |

SP 30-46 |

|

Quantity * Engine |

1 * 45 kW, |

|

|

|

|

Consumption |

31.33 |

м³/h ( +25%) |

|

H total |

342 |

м |

|

Power P1 |

46.31 |

kW |

|

Power P2 for work point |

39.36 |

kW |

|

Curve (nominal) |

89.5 |

A |

|

Cos fi (real) |

0,86-0,86-0,83 |

|

|

Saturated efficiency |

74.0 |

% |

|

Engine efficiency |

85.0 |

% |

|

Total efficiency |

62.9 |

% = Eff. real* Eff. elec. motor |

|

Total consumption |

91250 |

м³/year |

|

Specific energy consumption |

1.7743 |

kW.h /м³ |

|

Power consumption |

161910 |

kW.h /year |

|

Price list without VAT |

on request |

|

|

life cycle cost |

86076 |

€ /10 year |

|

Heating profile |

||||||

|---|---|---|---|---|---|---|

|

|

1 |

|

|

|

|

|

|

Consumption |

100 |

|

|

|

|

% |

|

Pressure |

120 |

|

|

|

|

% |

|

P1 |

44.36 |

|

|

|

|

kW.h |

|

Overall efficiency |

62.7 |

|

|

|

|

% |

|

Hours |

3650 |

|

|

|

|

h/y |

|

Power consumption |

161910 |

|

|

|

|

kW-y/year |

Output. According to the briefing review, it was found that the extraction of petrothermal energy is considered poorly understood. This paper presents a hydraulic calculation of a pipeline for transporting petrothermal energy according to the pipe-in-pipe scheme.